- Home

-

Products

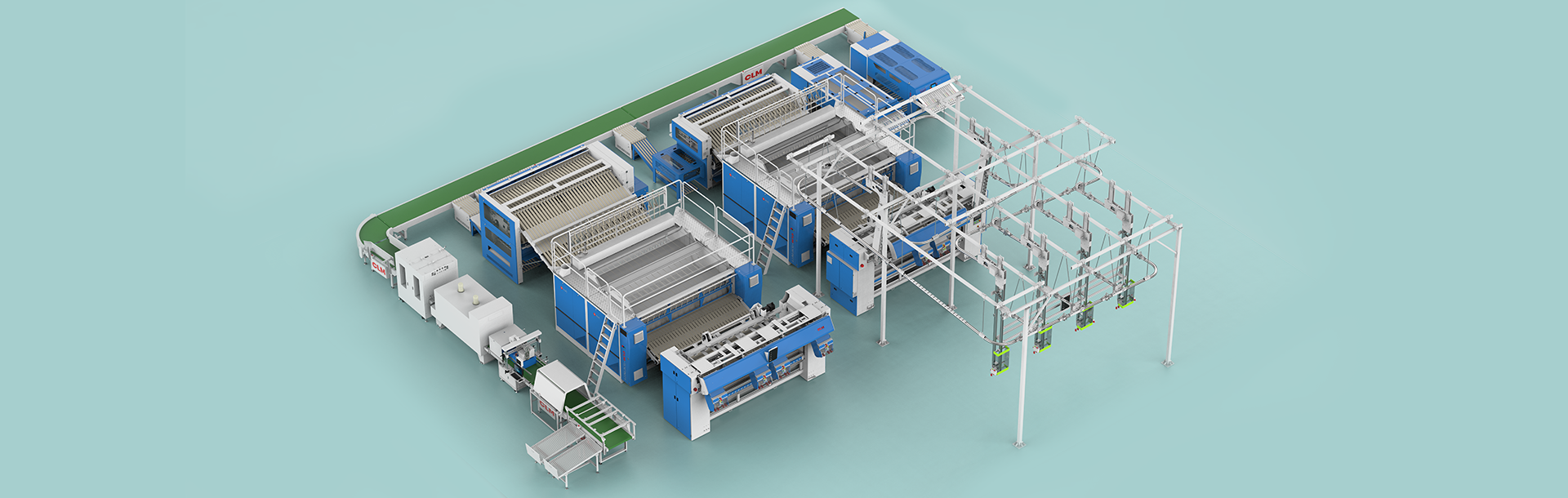

Tunnel Washers system

Tunnel Washers system

Ironing Line Series

Ironing Line Series

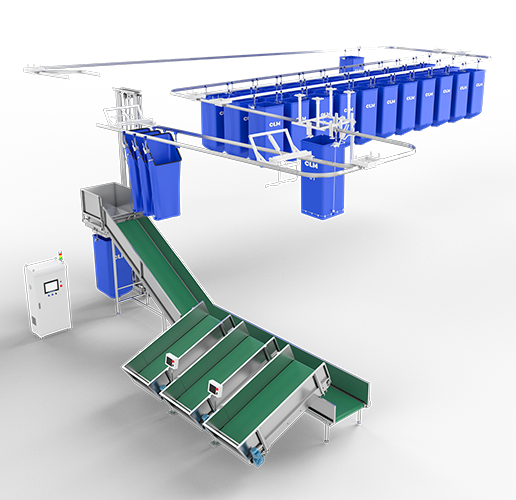

Laundry Bag system

Laundry Bag system

Garments Finishing Line

Garments Finishing Line

Industrial Washer Series

Industrial Washer Series

Self-Service Washer Series

Self-Service Washer Series

![{'$v['title']'}](/static/upload/2023/05/19/202305193675.png)

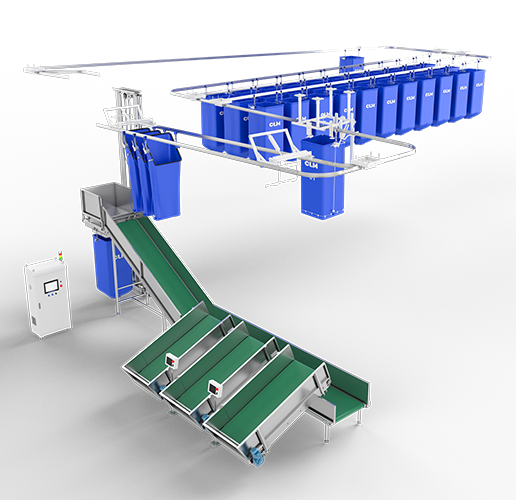

Loading Conveyor

![{'$v['title']'}](/static/upload/2025/08/21/202508216835.png)

Hotel Series 80Kg tunnel washers

![{'$v['title']'}](/static/upload/2024/12/18/202412188052.png)

Frame-type Press Extractor

![{'$v['title']'}](/static/upload/2023/05/19/202305198418.png)

CS-602 Shuttle Conveyor

![{'$v['title']'}](/static/upload/2025/08/21/202508211719.png)

Steam Heating Tumbler dryer

![{'$v['title']'}](/static/upload/2023/06/02/202306021297.png)

Lint Collector

![{'$v['title']'}](/static/upload/2025/08/21/202508216245.png)

Steam Heating Flexible Chest lroner

![{'$v['title']'}](/static/upload/2024/12/18/202412184078.png)

Single Lane Spreading Feeder

![{'$v['title']'}](/static/upload/2025/08/21/202508211970.png)

Gas Heating Chest Ironer

![{'$v['title']'}](/static/upload/2025/08/21/202508216245.png)

Steam Heating Fixed Chest lroner

![{'$v['title']'}](/static/upload/2025/08/21/202508215723.png)

Towel Folder With Mechanical Folding Blades

![{'$v['title']'}](/static/upload/2024/12/18/202412184810.png)

Series Folder

- Solution

- Service and Support

- About us

- Human Resources

- Contact Us

![{'$v['title']'}](/static/upload/2025/05/15/202505153828.png)

![{'$v['title']'}](/static/upload/2024/12/18/202412182363.png)

![{'$v['title']'}](/static/upload/2023/05/22/202305223243.png)

![{'$v['title']'}](/static/upload/2023/05/23/202305237565.png)

![{'$v['title']'}](/static/upload/2025/08/21/202508217458.png)

![{'$v['title']'}](/static/upload/2025/08/21/202508218793.png)

![{'$v['title']'}](/static/upload/2025/08/21/202508217878.png)

![{'$v['title']'}](/static/upload/2025/08/21/202508214701.png)

![{'$v['title']'}](/static/upload/2025/08/21/202508214403.png)

![{'$v['title']'}](/static/upload/2025/08/21/202508219554.png)

![{'$v['title']'}](/static/upload/2025/08/21/202508211155.png)

![{'$v['title']'}](/static/upload/2025/08/21/202508211103.png)

![{'$v['title']'}](/static/upload/2025/08/21/202508213316.png)

![{'$v['title']'}](/static/upload/2025/08/21/202508213117.png)

![{'$v['title']'}](/static/upload/2025/08/21/202508218823.png)

![{'$v['title']'}](/static/upload/2025/08/21/202508217246.png)

![{'$v['title']'}](/static/upload/2025/08/21/202508212310.png)

![{'$v['title']'}](/static/upload/2025/08/21/202508219383.png)

Hotel Laundry

Hotel Laundry Hospital Laundry

Hospital Laundry Institutional Laundry

Institutional Laundry Commercial Laundry

Commercial Laundry Laundromats

Laundromats Laundry Factory to Join

Laundry Factory to Join

After-sale Service

After-sale Service Service Parts

Service Parts

Enterprise Overview

Enterprise Overview Corporate culture

Corporate culture Honors and Certifications

Honors and Certifications Corporate News

Corporate News

Talent concept

Talent concept Join us

Join us